Sustainability

Insights 02.01.2024

Key Considerations for Going Electric

Jackson Reid

Demetrios Stamatakis

Never stop learning and questioning—a GLY value that applies to every aspect of our work. Steel erection is no exception.

Yes, we erect steel repeatedly with our trade partners in an efficient and safe manner, making it hard to discern areas for improvement. But because we believe we can always do better, we set out to collect data that would help point us in the right direction.

Thanks to emerging technologies, we can collect data that matters around processes that were once understood only imprecisely. The abundance of information now at our fingertips has led to interesting discoveries—be it finding areas for improvement or simply confirming our current methods.

For the last three years, we studied our crane pick processes and results using Versatile's CraneView technology, via its Lighthouse program for early adopters. CraneView is a device that attaches to the hook of a tower crane and measures thousands of construction data points with each pick cycle. The information, which includes time spent per pick, load weight, type of load, and other variables, along with a host of data and visualization tools—supplies detailed performance analysis in both real time and aggregate. The camera attached to the crane covers much of the site, anywhere picks happen, including steel placement from bottom up.

CraneView attaches to the hook of a tower crane and measures thousands of construction data points with each pick cycle.

In those years, we ironed out the details of both our work approach and CraneView data collection and applied these to projects going forward. This led to ever-better results on recent projects such as a 12-story office building in Seattle and a multi-tower project that recently topped out in Bellevue, all structural steel around concrete cores. Both show our steel erection subcontractor The Erection Company [TEC] and GLY field teams to be highly efficient.

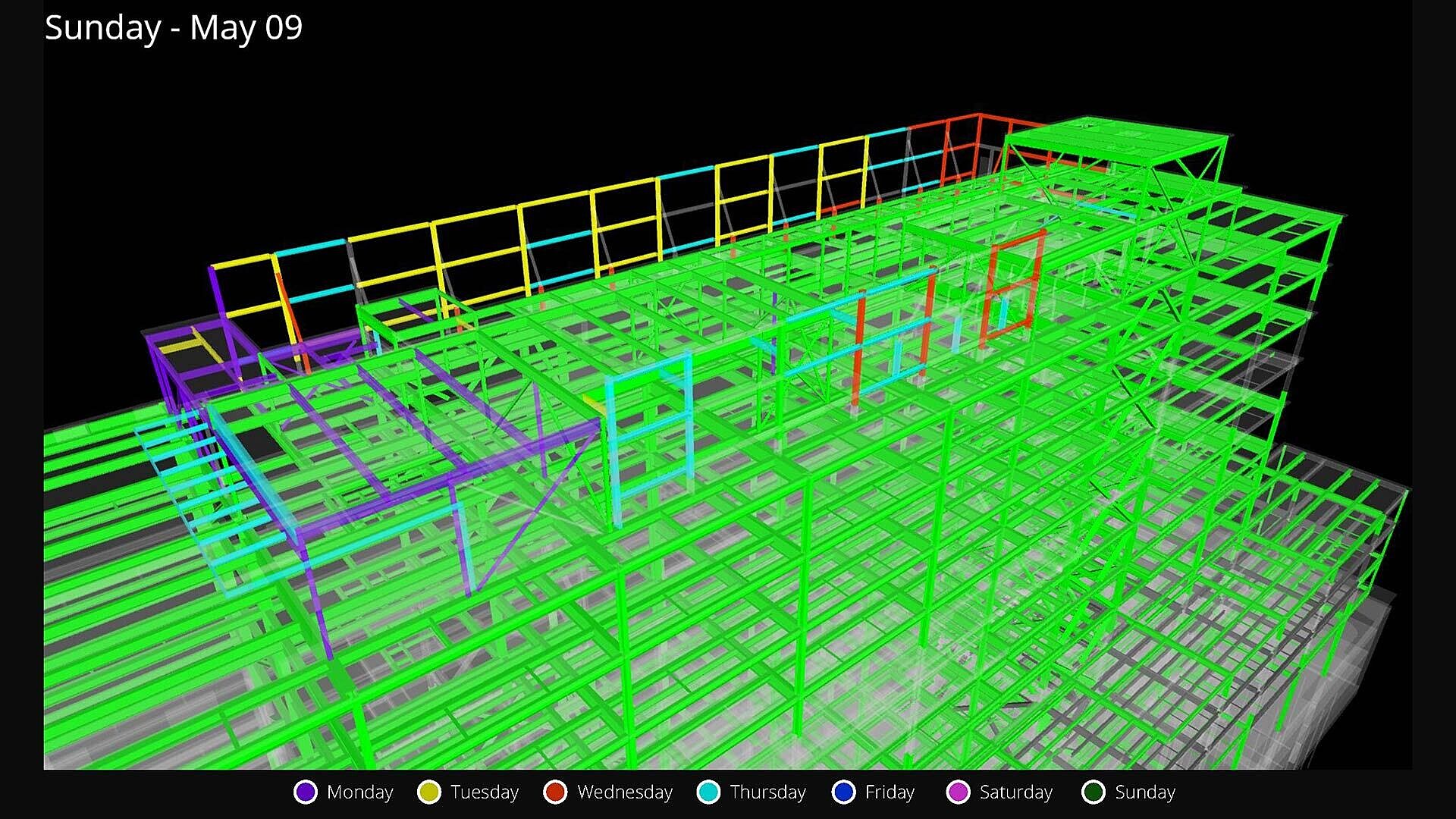

The CraneView dashboard provides 4D visuals to communicate weekly installation progress.

A 2020 Stanford University study titled “CEE241 – Managing Fabrication and Construction” further confirmed our own analyses. Students had access to our tower crane data from erection of crane through to the podium level on the 12-story office building. Their data and analysis showed that the central success factors were site management and site organization, as we believed.

TEC is a subcontractor who leverages an efficient jobsite for the max benefit of project owners. At the 12-story Seattle project, our metrics safely beat every other similar steel structure across the Northwest and nation.

This was not a fluke. Versatile reviewed the multi-tower Bellevue project in 2021-2022 against similar criteria, and TEC and GLY once again came out as best across all the towers erected. The learnings and processes similarly unfolded on an even more complex and constrained jobsite. We once again set the stage through field logistics and coordination.

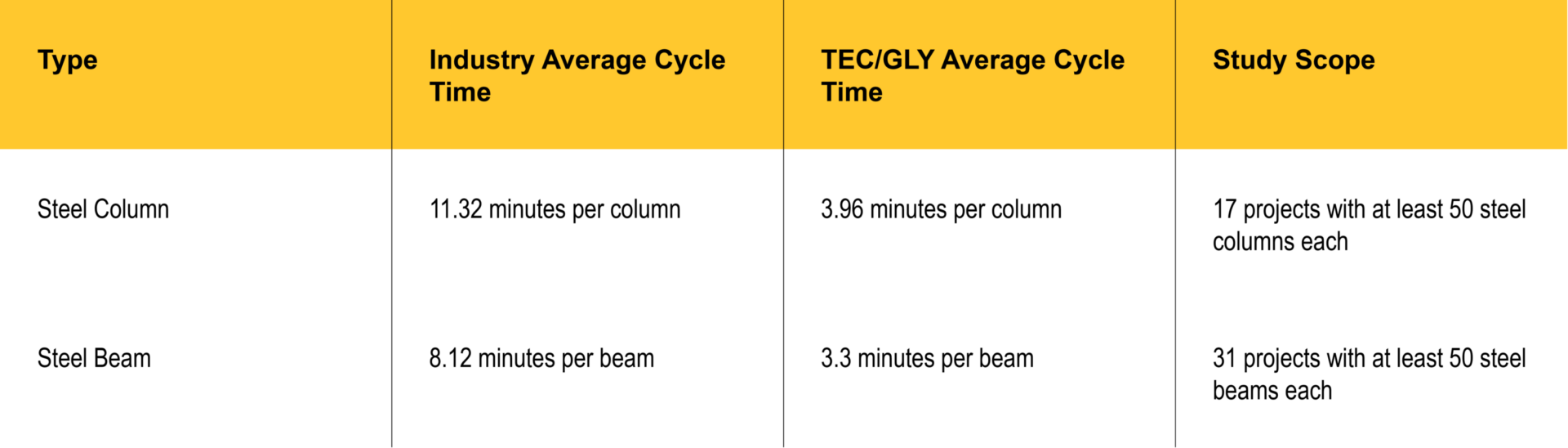

Versatile provided some metrics about our projects vs. industry average:

So, what does highly efficient really mean and how do we get there?

Well-Managed Crane Usage

The tower crane is the heart of any project, but there are only so many hours in the day to cycle loads. Every minute needs to be used wisely and effectively to keep every trade on track. That requires a detailed schedule and hardworking team including fast, safe rigging/unrigging and constant communication—all in rhythm like a heartbeat.

We used CraneView to measure our production and show efficiencies. We successfully focused crane time on high-priority picks, and optimally handled lower-priority picks such as trash receptacles in non-peak times.

The data led to other useful discoveries. If the crane doesn’t move for 15 minutes or picks are taking too long, we can watch the video or talk to the people involved to figure out why. We can also use the data to plan crane schedules and support conversations with subcontractors.

Sometimes we find issues not related to the crane. For example, we noticed a steel beam with a factory-applied flange installed out of sequence on the first floor of an office project. This turned out to be the result of a minor but necessary field modification that took place just prior to the beam installation, an inefficient process we didn't want to repeat. Rather than perform the same modification on every level of the building, TEC quickly altered the factory fabrication for new pieces so the beams could be installed upon delivery. The feedback loop worked!

Efficient Site Logistics

If the crane is the heart, site laydown and delivery areas are the lungs. Everything needs to be orderly, with room for movement and no wasted efforts. We can't waste crane time moving things repeatedly so we plan deliveries in great detail, plan laydown spaces down to the minute, and store materials offsite if needed.

The analyses also showed our current processes were maximizing laydown efficiency. Successful site care, custody, and control results in clean, clear, and accessible project sites, which helps critical path subcontractors effectively execute their work.

The data helped identify small efficiencies on each site through the visuals and analytical tools. More significantly, it's allowed us to define best practices that we can continue on every project.

By planning deliveries and site laydown down to the minute, project teams prevent wasting valuable crane time on repeatedly moving materials.

Every project is new. At GLY we carry forward best practices and lessons but can't rest on our laurels. That means always reviewing our performance honestly, and always looking for ways to improve. Constant technology research and development is part of that.

Diving deep into tower crane AI with CraneView over the last three years resulted in a clean bill of health—on those projects. That doesn't mean “all clear, pizza and burgers from now on!” but rather a good snapshot of where we've been, identification of critical best practices, and new insights to build upon.

We're also looking at using CraneView to study other trades such as curtainwall. This isn't so straightforward, as smaller on-floor spider cranes are often used for curtainwall to alleviate tower crane needs, but initial studies for using the main crane show promise with potential schedule advantages. We're looking into a more detailed analysis.

These three years have also been a study in how and why to use innovative technologies to best serve our clients. GLY is always evaluating new tools with a pragmatic, studied approach—is it useful to our teams, with better results for clients? Is the value to cost ratio realistic or lopsided, and which projects might benefit? Is a technology a solution in search of a problem or a true innovation?

Tags: