Collaborative Delivery

Insights 06.14.2022

Design-Assist: It’s a Team Sport

Adam shares the benefits of early engineer and trade partner involvement on cost, quality, and schedule.

Read More

A picture is worth a thousand words. The same is true in construction and design communication. When we visualize a space with the potential to make a difference in our communities and change lives, our ability to communicate building data and instructions accurately, effectively and efficiently is critical to a successful outcome.

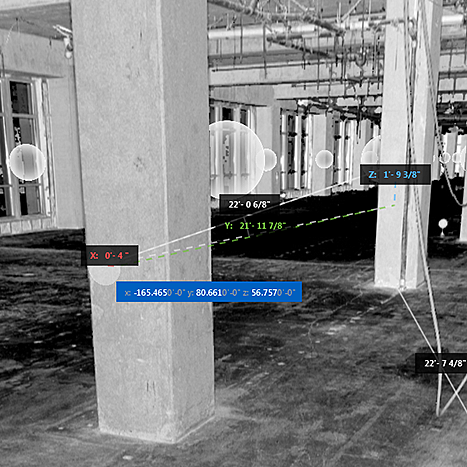

Laser scanning changes the game, allowing us to identify and digitally reconstruct every minute aspect of a building, from the exterior materials, to the internal wiring. With this powerful tool GLY continues to pioneer new applications of advanced technology to improve architecture and construction processes and provide the best possible service to clients.

GLY’s FARO Technologies Scanner allows us to develop a 3D diagram of the structure to create a detailed picture of as-built and complicated tenant improvement [TI] conditions. This enables us to review the entirety of reinforcing, conduit, and pre-installed hardware. On shell and core projects we use scanning both prior to and after pouring concrete, allowing for greater precision during construction, and highly accurate 3D records once construction is complete. With this technology we are delivering far more in-depth, relevant and accessible building information to our clients, building managers, owners, and anyone working on future construction on the same structure.

GLY’s FARO scanner at work—documenting the as-built conditions.

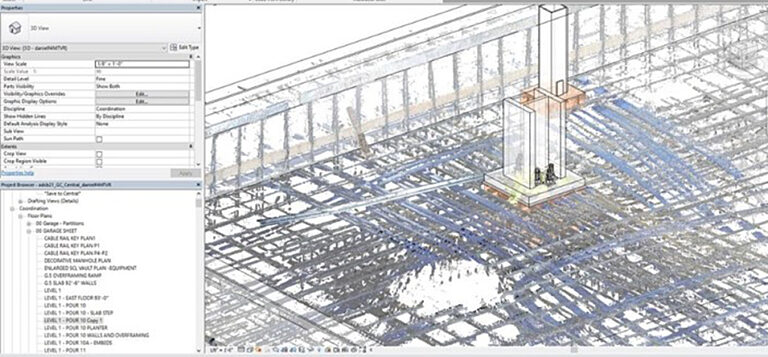

The resulting 3D model.

On complex TI projects like Two Union Square, applying this technique during early preconstruction allows us to work with the design team and MEPF design partners, to scan and digitally construct the entire building, discovering and resolving conflicts, maximizing synergies and identifying potential improvements prior to construction. The technology immerses the entire team in a digital “experience” of the building, creating a common language and visual aid that greatly empowers team communication and mitigates risk in the most efficient way possible.

The team used highly accurate as-built documentation via the FARO scanner to develop fabrication drawings for the custom stone walls and radiused diffuse ceiling material at Two Union Square.

Completed Two Union Square Lobby. Photo: © KEVIN SCOTT - All Rights Reserved.

Throughout construction our project engineers, design engineers and layout teams collaborate to scan continuously for quality control [QC], allowing us to confirm that we are installing elements correctly and accurately the first time around. Beyond QC, this continuous scanning helps to identify the structural elements within the layers of finishes with a high level of accuracy, making it easier to plan future work and adaptations.

By the end of construction, GLY has created a comprehensive, visual database of the entire structure that can greatly improve the efficiency of future building phases or revisions and provide valuable historic information to our design partners. We can resurrect details where site photography may have missed information and provide a reliable review for the Structural Engineer if they want to step back and identify or reassess the content inside a concrete deck. Building an accurate model of existing conditions also allows more exact dimensions, alignments, and helps avoid issues during clash coordination.

A comprehensive, visual database captures the exact built conditions of a new structure.

This technology has demonstrated its value in solving several complex project challenges. We were tasked with replicating an existing media production room in a new space, where crucial geometry needed to be perfectly replicated to ensure the highest sound quality. Traditional methods missed key elements, but by using scan data we were able to fill in the missing details and provide real world geometry to optimize the quality of the sound room that was to be built at a different site.

This is a tremendously exciting technology and we are pioneering efforts to find further applications and push it to do more for team collaboration, communication and risk mitigation. Its potential to offer our clients greater benefits in terms of efficiency and accuracy in the building process are clear but we also have great ambitions for its potential in managing the building life cycle. We are exploring ways to deliver high quality, relevant data for more efficient building operations and maintenance over the long term that will change the game of building management.

Layout Superintendent

Dan is GLY’s go-to guy for anything and everything relating to site surveys and layout. As a consummate team player and expert on layout technology, Dan is responsible for not only planning and coordinating project needs with superintendents, but also for training and educating the GLY Layout Crew and helping The Yard with long range equipment planning. When he’s not out in the field, Dan is 100% family man, spending as much time with his wife and kids as he can.