Collaborative Delivery

Insights 12.04.2024

Seismic Upgrades: Building Resilience for Safer Schools

Read More

Every firm and team member on a project brings diverse perspectives to the table. When to bring this valuable insight into the design and building process varies and is often determined by contract method: Design-Build, Design-Assist, or Design-Bid-Build. Each has its pros and cons and depending on project size and complexity there is often a best-fit approach; however, experiencing time and again the positive impact of early engineer and trade partner involvement on cost, quality, and schedule, GLY takes full advantage of Design-Assist efforts when possible, regardless of whether it is an owner requirement.

The concept is simple and the positive impacts are extensive.

In Design-Bid-Build, the architect designs up to a certain point—the Construction Documents, which trade partners use to bid and build their scopes of work. While efficient and straightforward, the downside of this approach and its lack of early trades involvement from various scope experts—MEP in particular—is overlooked constructability issues and missed opportunities for optimal solutions. This can lead to increased RFIs, change orders, and redesign.

The potential impact on the project? Schedule delays, increased costs, and stress.

With Design-Assist, communication starts much earlier. The general contractor facilitates the inclusion of various engineers and trade partners at appropriate times during the design phase to provide their expert input and recommendations—addressing issues before bidding and building the project.

The true benefit of this approach is that it sets you up for success down the line. Whether during clash detection or actual installation, the project as a whole benefits from feedback from the field.

Using the Design-Assist approach seems like a no brainer. So why not use it on every project?

First off, not every project might warrant the effort. It requires additional time from the general contractor and the design-assist partners asked to participate. Fitting in one or two more meetings a week isn’t easy these days. However, on projects with large teams, expedited delivery, abnormal contract conditions, complex MEPF systems or structural elements, intricate connections, or early procurement needs, Design-Assist is highly beneficial. Addressing issues early on will prevent course-correcting overlooked problems later in construction.

Second, Design-Assist is only beneficial if all parties buy in to the process. For example, a contract might specify the Design-Assist partnership between the general contractor, mechanical contractor, and electrical contractor for standard due diligence on pricing, constructability, and ROM strategies. While this is valuable on its own, for optimal results, the Engineer of Record [EOR] and initial MEPF designer need to take it one step further and actually implement recommendations. Design-Assist, unlike Design-Build, is simply that—providing assistance and influence through recommendations. It is up to the EOR to decide whether or not to make any changes to the final design documents.

To better understand the positive impacts of Design-Assist—for Owner, designers, trade partners, and the general contractor—let’s look at the recent work on the Thermal Energy Center [TEC], a massive heating and cooling hub for a confidential high-tech client. This project provided every ingredient to warrant a Design-Assist contract:

The TEC is a project of a lifetime. Getting buy-in for Design-Assist wasn’t a problem. Every firm involved wanted a successful outcome; however, agreeing to meet on a regular basis to flush out issues and reach this successful outcome also required an open mind and spirit of innovation. It opened the door for modifications to an individual’s or firm’s hard work. This wasn’t always an easy pill to swallow. But once everyone realized design adjustments were in the best interest of the project as a whole—a trust fall of sorts—hesitation to meet on a weekly basis quickly dissolved.

The weekly Design-Assist meetings with the Owner representatives, architect, engineers, and numerous trade partners during the Design Document and Construction Document phases quickly became the primary venue for questions, problem sharing, and suggestions. It provided a go-to place to figure things out instead of working in silos. This informal environment of idea exchange without holding back resulted in expedited construction document issuance, reduced exposure to future RFIs, and better cost certainty for the Owner.

The three examples below demonstrate the value realized from this time together. The best part? Each of these benefits is achievable on projects of a much smaller scale.

Near the completion of Construction Documents, the team realized the lack of a clear pathway for the Owner to replace large, heavy electrical equipment in years to come. The original approach of cutting through floors and interior walls proved complicated and costly. GLY, design team, and Owner used the Design-Assist meetings to talk through other options and agree on the optimal solution of cutting through a single exterior wall. In just one meeting, the team received buy-in and eliminated the financial impact, coordination challenges, and design changes that plagued the initial approach.

The TEC was a once-in-a-lifetime project not only for its MEPF systems but also because of the design team’s intent to go green—literally. Specs called for painting the entire MEPF system green. This ambitious effort is more than just applying paint. To release an RFP that provided enough detail for accurate estimates, GLY needed more information. For example, what was the true extent of the green paint? What would be pre-finished vs. painted in the field? What substrates would be in the interior thereby driving paint types? The Design-Assist meetings provided clarity and critical feasibility feedback from subcontractors. In the end, GLY distributed the final RFP to trade partners after releasing the 100% complete Construction Documents and benefited from a more realistic painting scope and improved specifications.

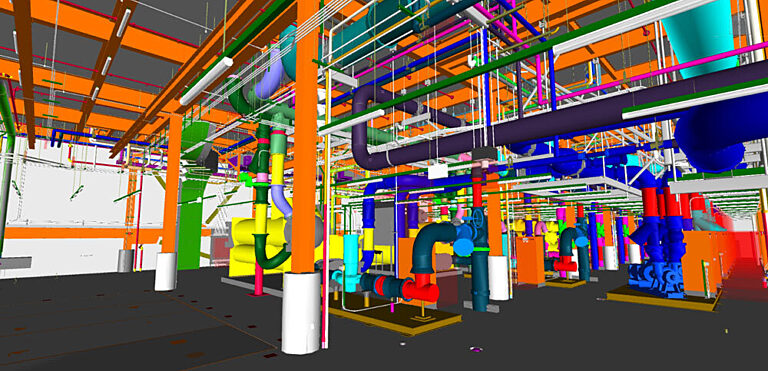

One of two major equipment rooms as seen from the only public view of the project. This room will be the primary showcase for the green-painted MEP infrastructure.

Ditch the Vacuum for Efficient Problem Solving

It’s a given for issues to surface daily on a project of this size and complexity. Working in a vacuum to address each issue—especially if individual decisions impacted another scope of work—is not an efficient approach. Instead, the team looked forward to the weekly Design-Assist meetings with all parties to work through problems. For example, take the major campus infrastructure that runs through the building. After exiting the TEC, the piping runs through a moat and concrete site wall then snakes its way below grade to an adjacent underground parking garage. Needless to say, the pipe routing required a major coordination effort—one reserved for Design-Assist meetings in the presence of the architect, structural engineer, civil engineer, landscape architect, general contractor, and mechanical subcontractor. With everyone dialed in, the team worked through various options and because of the highly visible collaborative environment, felt a sense of ownership in the final solution.

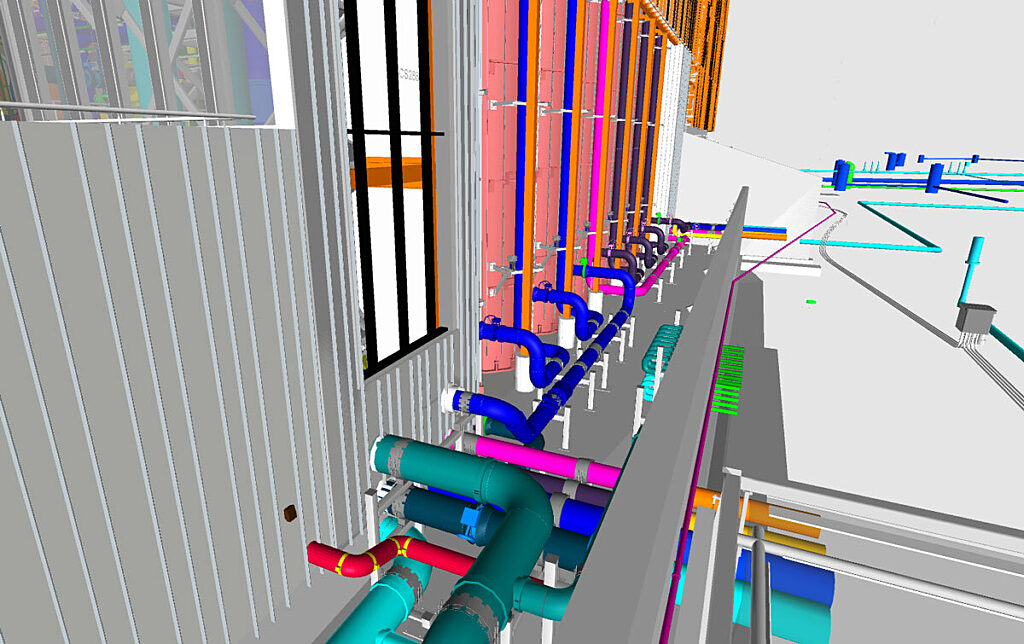

Major campus infrastructure exiting the TEC and starting its journey towards the garage and the rest of the campus’ buildings.

Do you have a project warranting Design-Assist? Want to learn more about the process in general and its many benefits? Reach out to Project Engineer Adam Stoeckle, AIA, LEED Green Associate on LinkedIn.